At the core of Azentio WMS lies a unified warehouse intelligence layer designed to orchestrate inbound, storage, picking, packing and dispatch processes with precision and scale. It connects space, stock, labor and movement into a single operational framework, eliminating silos and enabling:

The result is a warehouse that operates with agility, consistency and enterprise-grade control.

Warehouse environments are often constrained by manual coordination, picking inefficiencies, and fragmented visibility. Azentio WMS introduces structured automation and intelligent execution within a unified ERP backbone.

Optimized storage utilization through rule-based allocation and cube-fit logic

Improved operational efficiency through guided workflows and automation

Through intelligent wave planning and confirmation controls

By aligning warehouse execution with enterprise demand signals

Centralized inbound command dashboard

Automated put-away based on configurable business rules

Cube-fit and sequence-based storage optimization

Cross-docking to accelerate outbound fulfillment

Palletization and staging controls

Paperless receiving via handheld devices

Every inbound movement is synchronized with the ERP core ensuring real-time financial and inventory alignment.

Outbound operations are engineered for precision, compliance and speed.

Unified outbound control dashboard

Wave, batch, and order-based picking strategies

Priority-driven delivery scheduling

FIFO / FEFO allocation logic

Customer-wise order grouping

Automated zero-stock confirmation

This structured orchestration minimizes errors while accelerating dispatch velocity across channels.

As part of the Azentio OneERP suite, the WMS seamlessly connects with your enterprise systems. Within the Artisans Unified Commerce architecture, it functions as an intelligent execution layer to bridge warehouse operations with merchandising, planning and customer fulfillment.

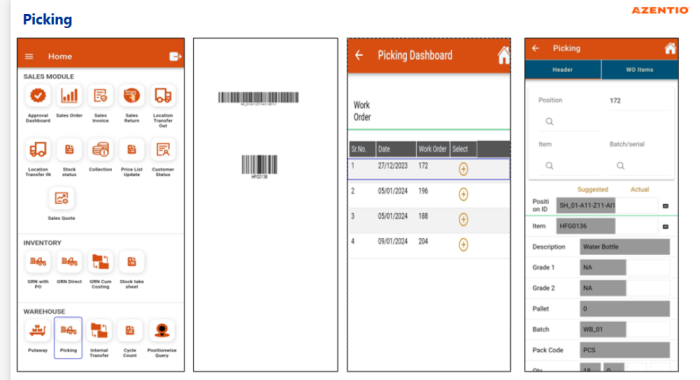

Designed for execution on the warehouse floor, Azentio WMS empowers teams through mobile-first workflows:

Handheld-based pick and put-away confirmations for warehouse floor execution.

Move inventory between zones and bins with instant system updates.

Eliminate manual paperwork with automated document generation and sequencing.

Generate barcodes and labels seamlessly for streamlined warehouse operations.

Operational updates reflect instantly across the enterprise system eliminating reconciliation gaps.

Warehousing is no longer a back-end function. It is a strategic driver of customer experience, margin protection and fulfillment excellence. With Azentio Warehouse Management System, integrated into the Artisans Unified Commerce ecosystem, enterprises gain:

Complete transparency across all warehouse operations and inventory movements.

Instant data alignment across all enterprise systems for unified decision-making.

Accelerated order processing and dispatch for improved customer satisfaction.

Optimized resource utilization and reduced operational overhead for long-term savings.

Transform warehouse execution into a connected, intelligent capability within your unified commerce ecosystem.